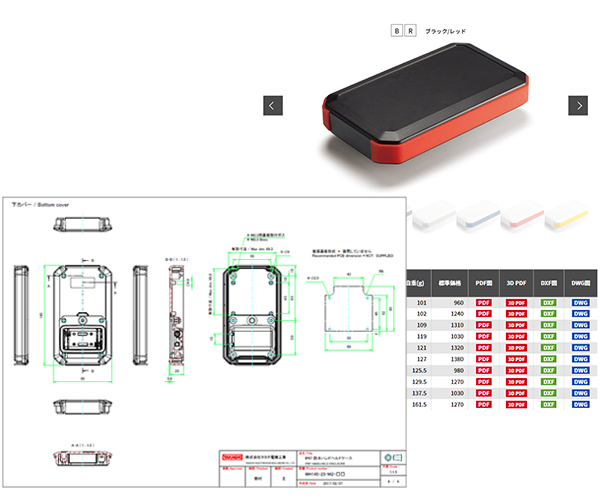

CUSTOMIZED ENCLOSURE・CUSTOM ELECTRONICS ENCLOSURE

- PHOTO GALLERY

APPLICATION EXAMPLE - INQUIRY FORM

- E-mail :

◆ Please type the e-mail address in manually.

- E-mail :

To fulfill your design requirements, We provide one-stop customization services, as machining/punching holes/cuts, printing, overlay manufacturing, painting or color anodization.

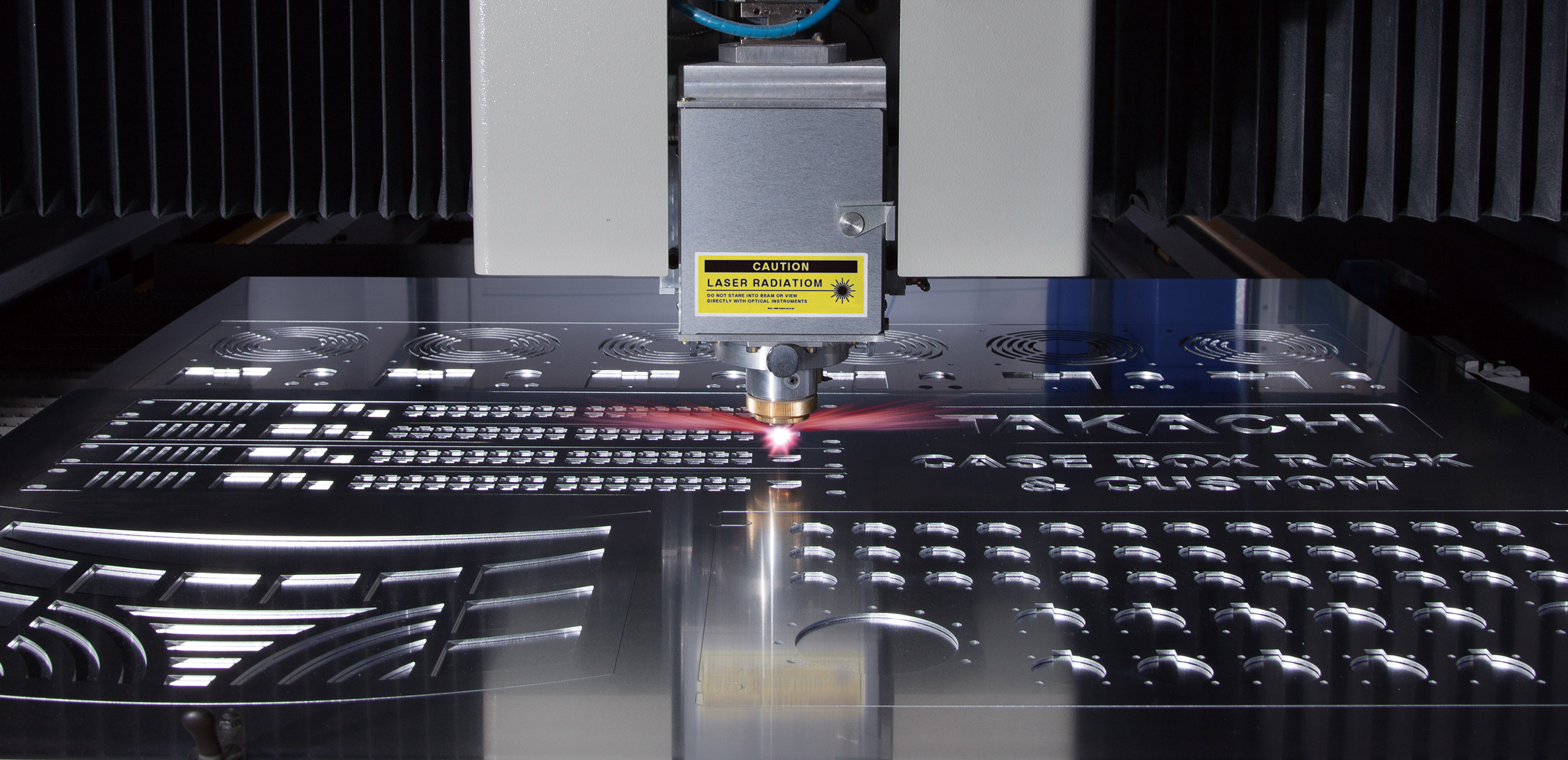

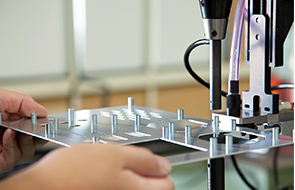

For holes/cut-outs, we can recommend the most suitable and cost-effective method from CNC Machining, Laser Cutting, or Punching press according to your requirements

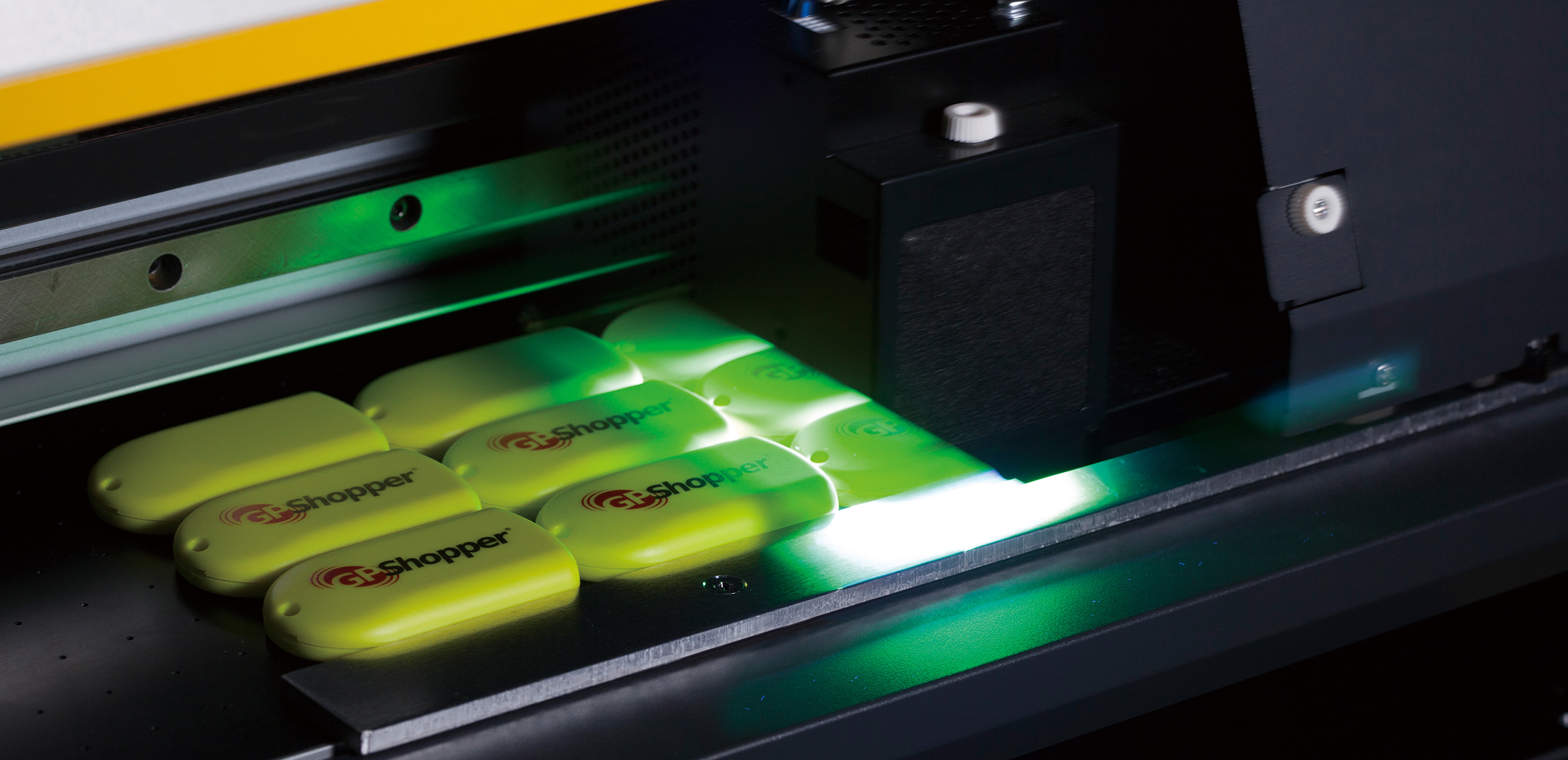

We also propose the most suitable and cost-effective Print/Marking solution from Inkjet printing, Laser marking, Silkscreen printing or Engraving.

THE TAKACHI CUSTOM ADVANTAGE

1. Over 48,000 product

We stock 99% of our products show on this website as off-the-shelf products.

We provide added-value enclosures in a short lead time by utilizing the stocked standard products.

2. Online CAD drawings

3D model and CAD format for standard enclosures are available on this website.

These drawings are prepared by separated parts to allow for easy-developing and drawing.

3. Latest facilities and machinery

With various types of machines and tools available, we are able to respond to your various requirements by providing quality and accurate customization.

Refer to the link PDF for lead time examples.

Process flow - from drawings submission to completion

submitted

CAM Programming

CAD/CAM machine.

Recommended format

| Data format | File version |

|---|---|

| DWG | LT2000~2018 |

| DXF | LT2000~2018 |

DWG / DXF

drawings can be downloaded

from our website

Notes

We customize our products based upon your specified details on your CAD drawings.

Kindly prepare your CAD drawings without any mistakes, such as size difference, location, type, etc.

Please also prepare both CAD and PDF drawings with all the measurements (hole size, location, etc) annotated;

- INQUIRY

-

- E-mail :

◆ Please type the e-mail address in manually.

- E-mail :