LASER CUTTING ・ CNC PUNCH PRESS ・ SHEET METAL PROCESSING

TAKACHI provides the most suitable and efficient sheet metal customization options depending on material and ordered quantity.

- INQUIRY

- E-mail :

◆ Please type the e-mail address in manually.

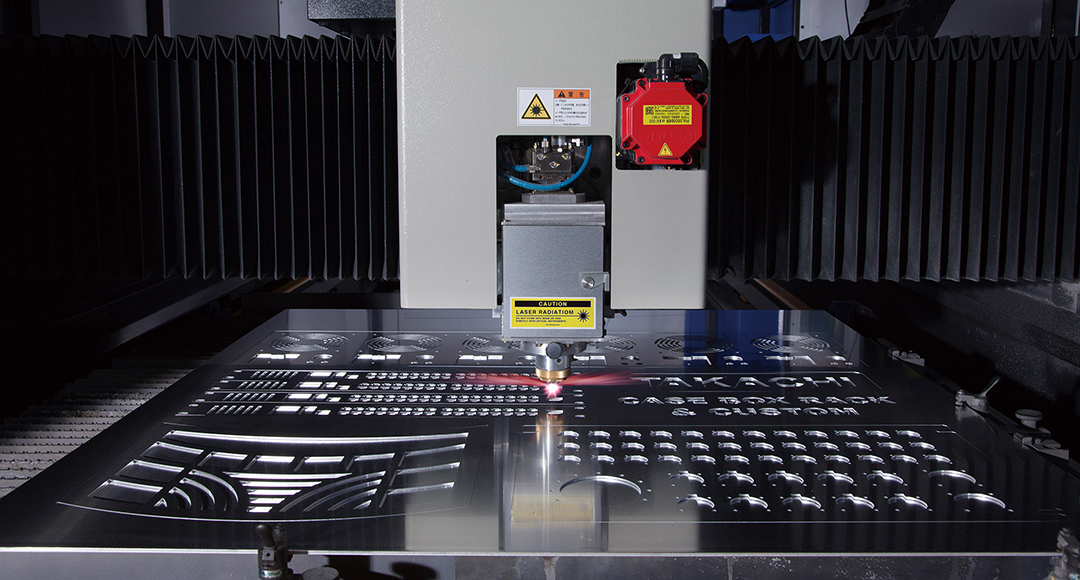

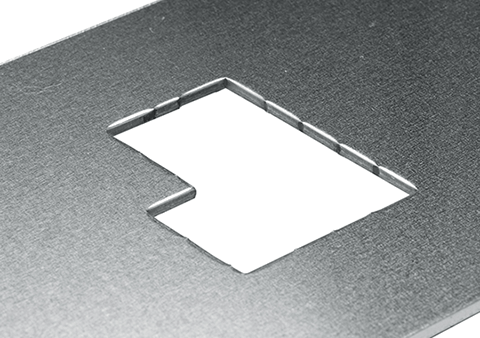

LASER CUTTING

Laser cutting utilizes a laser to perform cutting on an object, allowing various types and shapes of holes to be cut.

New fiber laser machine allows the processing of aluminium sheets with both high precision and speed.

Processing of Pure Aluminium 1050 is also possible with minimal burr as compared to conventional CO2 laser machines, which causes excessive burring.

- LASER CUTTING - VIDEOS

Fiber laser cutting - Aluminium panels

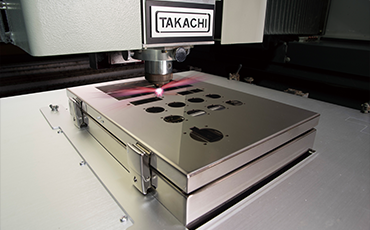

Laser cutting - Stainless steel box

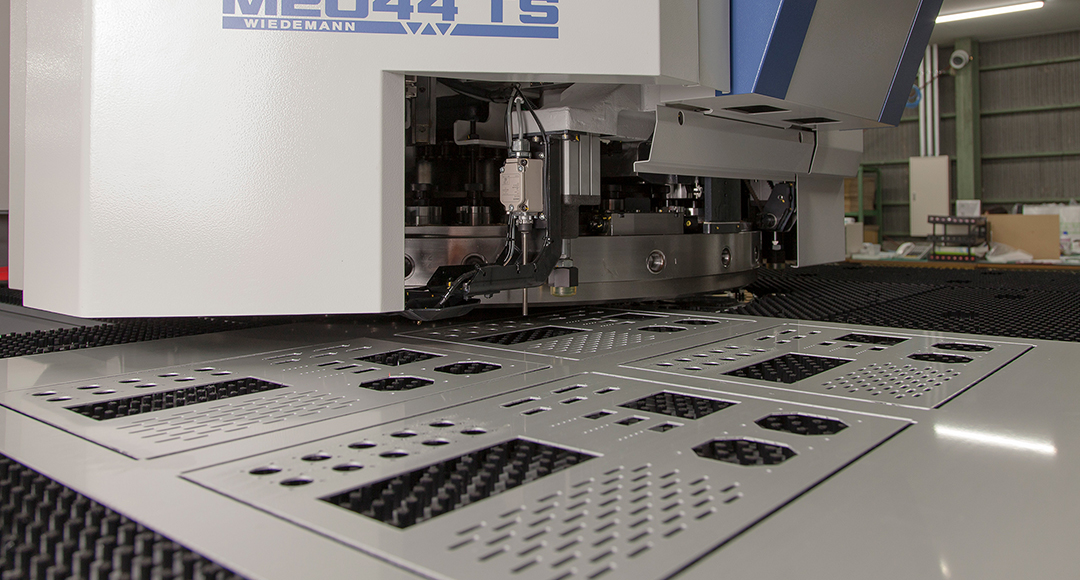

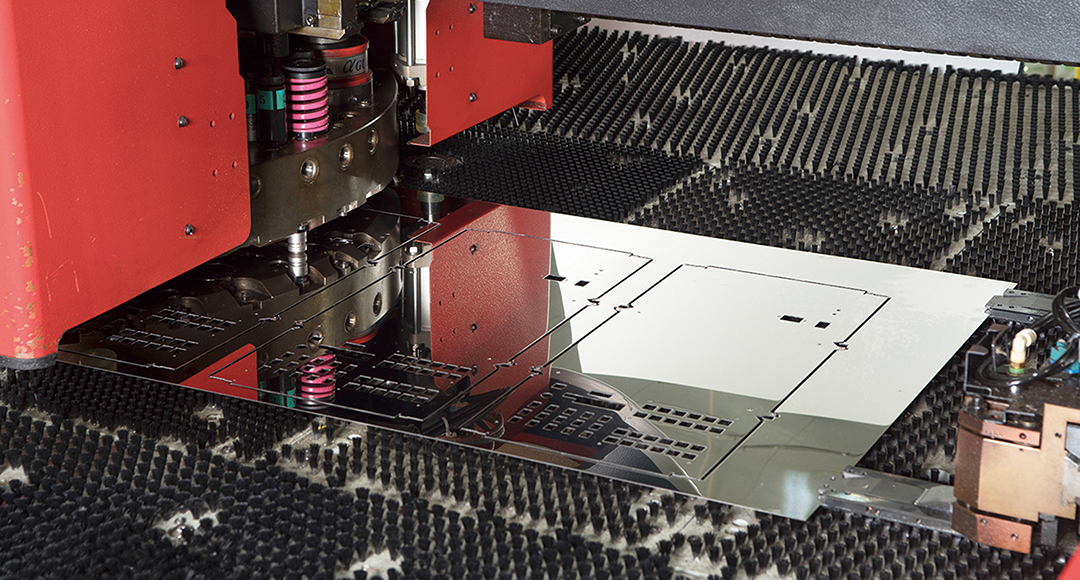

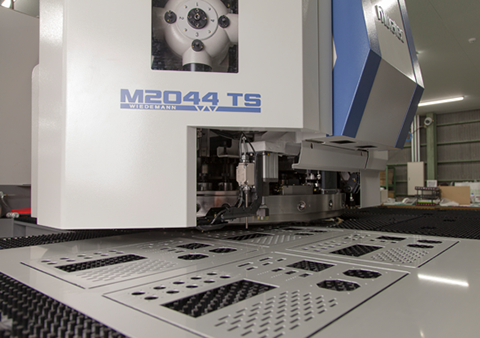

CNC PUNCH PRESS PROCESSING

What is Punch press processing? It is a type of machine press used to cut holes in material via the use of various sized die sets.

Punch press allows the realization of high cost performance due to its high speed automated turret punching process, which significantly reduces machining lead-time.

Due to its ability to create designated sized holes by means of rapid multiple hole punches, this enables it to punch holes of various sizes and types quickly and efficiently.

PUNCH PRESS PROCESSING - VIDEOS

CNC Punch press - Aluminium panels

CNC Punch press - Mass production

CUSTOM ALUMINIUM PANELS

TAKACHI provides custom aluminium panels from 50mm to 600mm in 0.1mm intervals from just 1 piece order with a short lead time.

Anodizing, painting, inkjet printing and/or engraving services are also available.